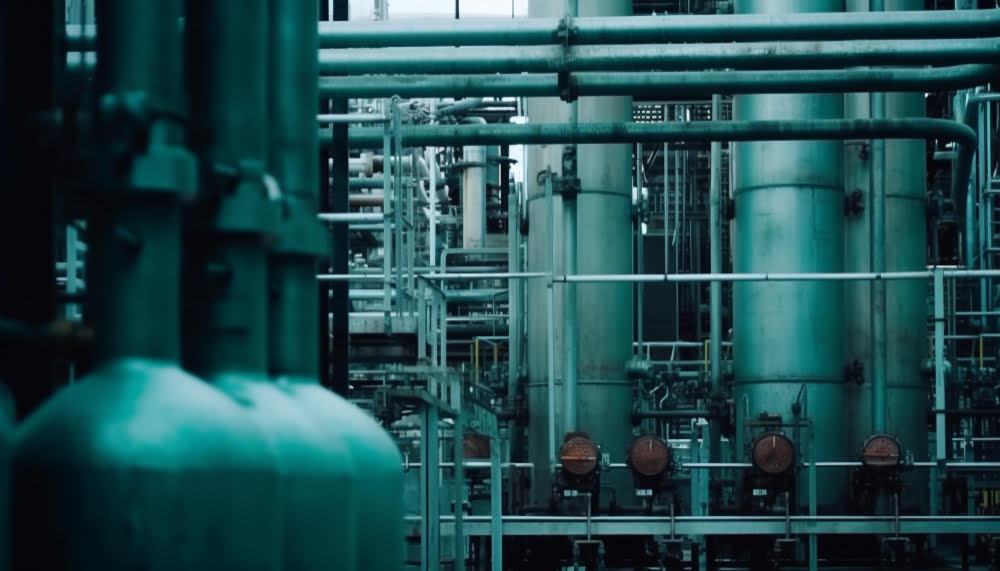

Bioethanol Plant

Bioethanol: The Renewable Energy of Tomorrow

Bioethanol, a renewable energy source, is produced from organic matter using state-of-the-art, energy-efficient production technology utilized in a biofuel plant in West Bengal. It is a readily available, clean-burning fuel for combustion engines that blends seamlessly with gasoline. It serves as a viable alternative to petrol in road transport vehicles, significantly reducing traffic-related greenhouse gas emissions.

MAGTECH’s Bioethanol Plant: Transforming Biomass into Biofuel

Our bioethanol plant in India employs the latest advancements in second-generation (2G) bioethanol technology. Unlike first-generation (1G) bioethanol production, which relies on food crops like corn and sugarcane, 2G bioethanol is produced from inedible agricultural residues34. This includes materials such as corn cobs, rice husks, wheat straw, and sugarcane bagasse.

These materials are converted into cellulose, which can then be fermented into ethanol and mixed with conventional fuels. This process not only provides a sustainable energy solution but also addresses the critical issue of agricultural waste management. These are why Bioethanol plant manufacturers are being endorsed as sustainable solutions.

The Process

An In-Depth Look

The production process in our bioethanol plant in West Bengal involves four major steps:

- Pretreatment

- Hydrolysis

- Fermentation

- Distillation

The lignocellulosic biomass feedstock undergoes pretreatment to prepare it for the subsequent processes. This involves breaking down the complex structure of the biomass and making the cellulose more accessible.

The pretreated biomass is then subjected to hydrolysis. This process involves breaking down the complex carbohydrates into simple sugars using enzymes. The result is a sugar-rich solution ready for fermentation.

The simple sugars are fermented by microorganisms to produce ethanol. This process is carefully controlled to ensure optimal conditions for the microorganisms.

The resulting mixture is distilled to separate the ethanol. The ethanol is then dehydrated to remove any remaining water, resulting in anhydrous ethanol ready for blending with gasoline.

Why Choose MAGTECH

Fueling the Future: Welcome to Magtech

Choosing MAGTECH’s bioethanol plant over other suppliers offers several distinct advantages:

- Innovation: At MAGTECH, we pride ourselves on our innovative approach to technology. Our bioethanol plant consultant in India leverages cutting-edge 2G bioethanol technology, setting us apart from competitors who still rely on 1G technology.

- Efficiency: Our biofuel plant operates with high efficiency, maximizing ethanol production while minimizing waste.

- Sustainability: By using agricultural waste as feedstock, our plant promotes sustainability and contributes to waste management solutions.

- Support: We provide comprehensive after-sales support to ensure your plant operates smoothly and efficiently.