Authors:

Soumya Kanti Roy, B-Pharm, Technical Content Writer

Dr. Sourav Barman, PhD (Chemical Engg.), Research Engineer (Magtech.)

Kunal Konar, ME (Water Res. & Env.), Strategic Partner (Magtech.)

Crude glycerine is the prime by-product of biodiesel transesterification production. A conventional method releases 1 kg of crude glycerol or glycerine for 10 kg of biodiesel produced. It is colorless, odorless, and viscous in nature. It has a sweet taste and is non-toxic in nature.

Glycerine is then collected in crude form from the waste of biodiesel production. Generally, the biodiesel manufacturing units sell the crude form to refineries to make high-grade concentrated glycerine.

This byproduct can be utilized to generate more income if sold in purified form. Let us find out what the crude glycerine uses are.

Table of Contents

ToggleUses of Crude Glycerine in Different Industries:

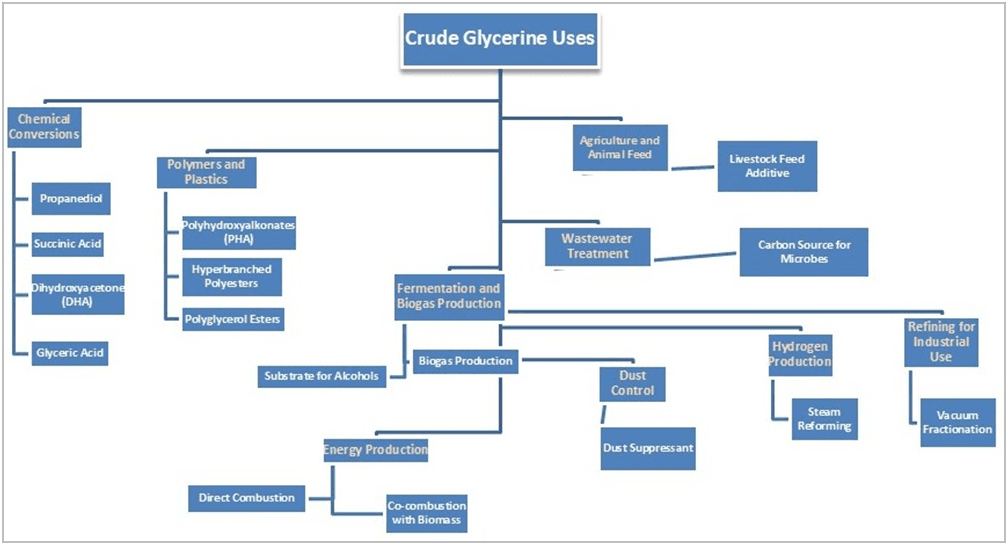

Crude glycerine uses in different industries as depicted in Figure 1 and further elaborated in the following subsections.

1. Chemical Conversions

- Propanediol (1,3-PD):

Two primary methods, biological fermentation, and chemical synthesis, produce propanediol from crude glycerin. In biological processes, specific microorganisms convert glycerin into 1,3-propanediol under anaerobic conditions. In chemical methods, glycerin undergoes catalytic hydrogenation; consequently, it transforms into propanediol through controlled reactions with hydrogen gas and catalysts at high temperatures.

Use of Propanediol:

Propanediol is a key ingredient in producing polytrimethylene terephthalate (PTT), a durable polymer used in textiles, carpets, and plastics. Due to its non-toxic and eco-friendly properties, it also serves as a solvent in personal care products, cosmetics, and cleaning agents.

In the food industry, it is used as a food additive and humectant. Additionally, 1,3-PD is found in adhesives, resins, and coatings, enhancing the flexibility and durability of these materials. Its renewable origin makes it a popular choice in green chemistry applications.

Figure 1: Uses of Crude Glycerine across various Industries

- Succinic Acid

Succinic acid is produced from glycerin primarily through biological fermentation using specific microorganisms. Bacteria metabolize glycerin under anaerobic conditions to convert it into succinic acid in this process. Chemical synthesis methods also exist, but fermentation is more common.

Use of Succinic Acid: It serves as a building block for producing biodegradable plastics, polyesters, and resins. In the food industry, succinic acid acts as a flavoring agent and acidity regulator. The pharmaceutical sector utilizes it to synthesize drugs and intermediates, including 1,4-butanediol, an important raw material in the production of solvents, plastics, and fibers. Additionally, succinic acid is employed in cosmetics and personal care products for its moisturizing properties. Its increasing demand is driven by the shift towards sustainable and renewable alternatives, making it a key player in green chemistry initiatives.

- Dihydroxyacetone (DHA)

Dihydroxyacetone (DHA) is produced from glycerin through biological processes or chemical synthesis. In biological methods, specific microorganisms ferment glycerin, converting it into DHA. Chemically, glycerin can undergo oxidation, often using catalysts, to produce DHA. Both methods utilize glycerin as a sustainable feedstock for DHA production, especially in cosmetic applications.

Use of Dihydroxyacetone: Dihydroxyacetone (DHA) is primarily used in the cosmetic industry as a self-tanning agent due to its ability to react with amino acids in the skin, producing a natural-looking tan. It is widely found in sunless tanning products and skincare formulations. Additionally, the food industry utilizes DHA as a flavoring agent and preservative; consequently, it enhances the taste and shelf life of certain products. Its non-toxic nature and biodegradability make it an attractive choice for manufacturers. Research also explores its potential applications in pharmaceuticals, particularly in drug delivery systems and as a precursor for various chemical syntheses.

- Glyceric Acid

Glyceric acid is produced from glycerine through oxidation processes, typically using chemical oxidants or enzymes. In industrial settings, glycerine undergoes selective oxidation, converting it into glyceric acid. This transformation can be facilitated by catalysts that promote the reaction; consequently, this allows for the efficient production of glyceric acid from glycerine as a renewable resource.

Use of Glyceric Acid: It primarily uses a building block in the synthesis of pharmaceuticals and cosmetic formulations; consequently, this is due to its moisturizing and skin-friendly properties. In the food industry, glyceric acid serves as a food additive, enhancing flavor and texture in various products. It contributes to environmentally friendly formulations; moreover, it does so by employing it in the production of biodegradable polymers and surfactants. Companies, therefore, utilize glyceric acid esters as emulsifiers and stabilizers in personal care products and cosmetics. Its versatility and low toxicity make glyceric acid a preferred ingredient in green chemistry initiatives.

2. Polymers and Plastics

- Polyhydroxyalkonates (PHA)

Polyhydroxyalkanoates (PHA) are produced from crude glycerine through microbial fermentation. Specific bacteria metabolize glycerine, converting it into PHA granules within their cells. Firstly, cultivate these microorganisms in controlled conditions in order to accumulate PHA as a storage compound. Subsequently, you can then harvest and process it into biodegradable plastics.

Use of Polyhydroxyalkonates: They serve as sustainable alternatives to conventional plastics in packaging, single-use items, and agricultural films. PHAs play a vital role in producing medical applications like sutures, drug delivery systems, and tissue engineering scaffolds; therefore, they are essential due to their biocompatibility and biodegradability.Moreover, the cosmetics industry uses them as emulsifiers and thickening agents to enhance product stability and texture. Furthermore, researchers are increasingly exploring phas; in addition, this trend is evident in the automotive and consumer goods sectors.

- Hyperbranched Polyesters

The polymerization process, therefore, produces hyperbranched polyesters from crude glycerine by reacting glycerine with diacids, such as adipic acid, in the presence of catalysts. Additionally, this method allows for enhanced properties in the resulting materials. This reaction results in a branched structure, allowing for a versatile range of properties. The resulting hyperbranched polyesters, consequently, find applications in coatings and adhesives.

Uses of Hyperbranched Polyesters: They serve as efficient materials for coatings, adhesives, and sealants, offering excellent adhesion and flexibility. Furthermore, hyperbranched polyesters in the pharmaceutical sector enhance the solubility and, consequently, bioavailability of active compounds in drug delivery systems. Their low viscosity and high functionality make them ideal for applications in cosmetics and personal care products, where they act as emulsifiers and moisturizers. Researchers are exploring these polymers, specifically in the production of biodegradable materials.

- Polyglycerol Esters

The esterification process, therefore, produces polyglycerol esters from crude glycerine by reacting glycerine with fatty acids or their derivatives. This reaction occurs under controlled temperatures and conditions, resulting in the formation of polyglycerol esters. These compounds, therefore, serve as effective emulsifiers and stabilizers in food, cosmetics, and pharmaceutical applications.

Uses of Polyglycerol Esters: In the food industry, they act as emulsifiers, stabilizers, and texturizers, improving the consistency and shelf-life of products like margarine, dressings, and baked goods. In cosmetics and personal care, polyglycerol esters not only enhance product stability but also provide skin conditioning properties in lotions, creams, and shampoos.They also use excipients in pharmaceuticals, aiding in drug formulation and delivery. Additionally, companies, furthermore, use these esters in producing biodegradable plastics and coatings.

3. Energy Production

Companies also utilize crude glycerin as a renewable energy source.

- Direct Combustion

Companies, therefore, burn crude glycerine in boilers for heat and, consequently, power generation. It serves as an alternative to traditional fossil fuels; consequently, it reduces environmental impacts.

- Co-combustion with Biomass

Combine glycerine with other biomass materials to produce syngas (a mix of carbon monoxide and hydrogen). Then, you can use syngas for further energy applications or produce hydrogen through steam reforming.

4. Wastewater Treatment

Crude glycerin plays a significant role in boosting microbial activities in wastewater treatment plants:

- Carbon Source for Microbes

It acts as a carbon substrate to help microbes break down organic matter. This is especially useful when communities experience spikes in wastewater volumes. It enhances the efficiency of wastewater treatment processes; consequently, it ensures cleaner discharge.

5. Agriculture and Animal Feed

Researchers are exploring the potential of crude glycerin uses in animal nutrition:

- Livestock Feed Additive

Crude glycerin used as a feed additive for pigs, hens, and ruminants. It provides an energy source without negatively affecting the animals’ health when used in controlled amounts. The FDA approves pure glycerin for use in animal feed, although crude glycerin may still contain impurities that require further regulation.

6. Fermentation and Biogas Production

Crude glycerin can use various fermentation processes:

- Substrate for Alcohols

It can serve as a carbon source for producing ethanol and butanol. These alcohols, therefore, are valuable in the energy and chemical industries.

- Biogas Production

When co-digested with waste streams like animal manure or sewage sludge, crude glycerin aids in the production of biogas. This approach provides a way to generate energy from waste while reducing environmental impacts.

7. Dust Control

Crude glycerin has found applications in reducing dust in industrial and agricultural settings:

- Dust Suppressant

Spray glycerin on dirt roads to reduce dust levels. As a biodegradable and non-toxic substance, it, therefore, degrades within weeks; consequently, this minimizes long-term environmental effects. However, concerns remain about the impurities in crude glycerin, which could pose health risks.

8. Hydrogen Production

Crude glycerin is a potential feedstock for hydrogen generation:

- Steam Reforming

Industries like pharmaceuticals, cosmetics, and food production use purified glycerin. This, in turn, adds to its value as an alternative energy source, especially in the transition to renewable energy systems.

9. Refining for Industrial Use

While crude glycerin contains impurities, refining can unlock more valuable applications:

- Vacuum Fractionation

Refining crude glycerin through vacuum distillation helps remove impurities. High-purity glycerin is the result, suitable for industrial use. Industries such as pharmaceuticals, cosmetics, and food production commonly use purified glycerin. However, refining is costly and may not be feasible for small- or medium-scale biodiesel producers.

New Dimensions for Biodiesel Production Profitability

crude glycerin uses opens new dimensions for profitability in biodiesel production. Crude glycerin is a by-product and often viewed as waste. However, recognizing its value leads to innovative applications across various industries, from biodegradable plastics to food additives and pharmaceuticals.

By exploring these opportunities, biodiesel producers can offset production costs and enhance their bottom line. The shift towards sustainable practices, consequently, aligns with global trends favoring eco-friendly products; thus, it makes glycerin-derived applications increasingly attractive.

As research continues to unveil more uses, the biodiesel industry can transform what was once a challenge into a significant revenue stream. Embracing crude glycerin’s potential not only supports economic viability but also contributes to a more sustainable future, reinforcing the importance of circular economies in energy production.

MAGTECH: The Best Solution Provider for Crude Glycerin Collection in Biodiesel Production

Unlock the full potential of your biodiesel production with MAGTECH’s reliable biodiesel manufacturing and in-situ crude glycerin collection, delivering a purity range of 60-80%. Leveraging our in-house R&D facility and collaborations with various institutes, we have developed an innovative, energy-efficient process for biodiesel production that also produces high-purity crude glycerin with minimal purification required.

This approach significantly boosts profitability by reducing operational costs and maximizing resource efficiency, while also enabling flexible and efficient processing of various feedstocks, ensuring adaptability to different raw materials without compromising on quality. Contact us today to learn more about crude glycerin uses to support your biodiesel journey and elevate your operations economically.

References

MEGA a.s., Czechia. (n.d.). Glycerin purification by MEGA electrodialysis. Retrieved from https://www.mega.cz/

Sofia Maria, I., Chrysanthi, P., Dimitrios, L., Harris, P., Maria, T., Vlysidis, A., . . . Koutinas. (2020). Sustainable production of bio-based chemicals and polymers via integrated biomass refining and bioprocessing in a circular bioeconomy context. Bioresource Technology, 123093. doi:https://doi.org/10.1016/j.biortech.2020.123093

Vijay Kumar, G., Uttara, S., & Amrita, B. (2016). Bioconversion technologies of crude glycerol to value-added industrial products. Biotechnology Reports, 9-14. doi:https://doi.org/10.1016/j.btre.2015.11.002

Xiaolan, L., Xumeng, G., Shaoqing, C., & Yebo, L. (2016). Value-added processing of crude glycerol into chemicals and polymers. Bioresource Technology, 215, 144-154. doi:https://doi.org/10.1016/j.biortech.2016.03.042

Yang, F., Hanna, M., & Sun, R. (2012). Value-added uses for crude glycerol–a byproduct of biodiesel production. Biotechnol Biofuels, 5(13). doi:https://doi.org/10.1186/1754-6834-5-13

Zhiyou, W. (2024). New Uses for Crude Glycerin from Biodiesel Production. Retrieved from Farm Energy: https://farm-energy.extension.org/new-uses-for-crude-glycerin-from-biodiesel-production/