India is moving fast toward a greener future with bioethanol. The government aims to achieve a 20% bioethanol blend in petrol by 2025.

To meet this goal, bio ethanol from food grains plant set up is offering a strong foundation by offering a strong alternative to sugarcane-based fuel. They use maize, broken rice, and other surplus grains. These plants help reduce oil imports, cut emissions, and support farmers.

This blog will cover how food grain–based ethanol is reshaping India’s fuel landscape and how MAGTECH can help you be part of this change.

Table of Contents

ToggleIndia’s Ethanol Blending Push: From E12 to E20

India’s ethanol blending program has seen rapid progress in recent years. In April 2023, the country reached a 12% average ethanol blend (E12) in petrol, a major step toward its green fuel goals.

By February 2025, blending levels had surged to nearly 19.7%, with some reports showing it touched 19.8%. This sharp rise reflects strong policy support, better infrastructure, and increased production capacity.

The government’s goal is to achieve 20% blending (E20) by 2025–26. This move aims to reduce crude oil imports, lower greenhouse gas emissions, and support energy independence.

To make this possible, ethanol production must scale up quickly. While sugarcane molasses was once the main feedstock, food grains like maize and broken rice are now playing a key role.

This shift is not only practical but also necessary, given sugarcane supply challenges and the need for alternative, sustainable sources.

Why Food-Grain-Based Ethanol Is in the Spotlight?

Food-grain-based ethanol is becoming more important in India due to shifting supply trends, government support, and economic needs. Here’s why this approach is gaining momentum:

- Sugarcane Supply Limitations

Drought and falling yields in sugarcane-growing regions like Maharashtra and Karnataka have reduced the availability of molasses for ethanol. This has pushed the government to look beyond sugar-based ethanol.

- Huge Grain Surplus

India produced a record 146.1 million metric tonnes of rice in 2024–25. Over 59.5 million metric tonnes are stored in government warehouses. Much of this includes lower-quality grains like broken rice and damaged stock, which can now be used for ethanol production.

- Policy Support

The government now allows the use of maize, surplus rice, and other food grains under the Ethanol Blended Petrol (EBP) program. In 2023–24, 57% of all ethanol produced in India came from food grains.

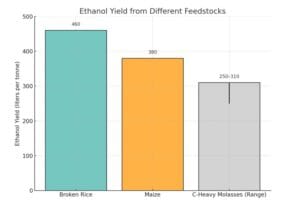

- Higher Yields

Broken rice can produce up to 460 liters of ethanol per metric tonne, while maize gives about 380 liters both of which are higher than molasses-based ethanol.

- Farmer Income Boost

Ethanol production from grains helped farmers earn over ₹42,000 crore in recent years by creating a new, reliable market for their crops.

These benefits are making food-grain ethanol a key part of India’s green energy future. The overall benefits make this green fuel production shift to food-grain-based feedstocks.

Let’s check the feedstock efficiency and sustainability benefits of this feedstock in detail.

Feedstock Efficiency & Sustainability Benefits

Using food grains like maize and broken rice to produce ethanol offers major advantages in both efficiency and sustainability. These benefits are not just technical—they are economic and environmental too. Here’s how food-grain-based ethanol helps build a greener and more secure energy future for India:

1. Higher Bioethanol Yield Per Metric Tonne

Grain-based ethanol offers better yields compared to traditional molasses-based ethanol. Here is the comparison of the bioethanol-yielding capacity of food grains.

This means plants using grains can generate more ethanol using less raw material.

- Better Water Efficiency

Producing ethanol from grains requires less water than from sugarcane.

- Sugarcane bioethanol uses about 3,000 liters of water per litre of ethanol

- Maize-based bioethanol uses only 2,570 liters per litre

This reduces the water stress in drought-prone areas and makes the process more sustainable.

- Lower Greenhouse Gas (GHG) Emissions

Switching to bioethanol helps reduce GHG emissions compared to petrol.

- Grain-based bioethanol can reduce emissions by up to 50%.

- Using surplus grains also prevents methane release from rotting grain stocks.

4. Circular Use of Surplus Stocks

India faces the challenge of managing large buffer stocks of food grains. Using damaged and surplus rice for bioethanol helps:

- Avoid grain spoilage and storage losses

- Save on government warehousing costs

- Support price stability in agricultural markets

5. Environmental Compliance & Cleaner Air

Blending bioethanol reduces particulate matter and carbon monoxide emissions from vehicles. This is especially important in polluted urban areas.

It’s a win-win situation for farmers and investors who want to establish a bio ethanol from food grains plant set up.

Tap into the growing market potential of this biofuel. Here is a glimpse of this segment.

Bioethanol Market Outlook & Investment Opportunity in India

India’s bioethanol market is undergoing a major transformation, offering strong opportunities for investment and long-term growth. With rising demand for cleaner fuels and strong policy support, the country is emerging as one of the world’s fastest-growing bioethanol markets.

- Strong Growth Forecast: The Indian bioethanol market is expected to grow from USD 2.3 billion in 2024 to USD 6.5 billion by 2033, with a CAGR of over 11.5%. This growth is driven by government mandates, rising fuel demand, and private sector investment.

- Rising Consumption: Bioethanol demand is projected to increase from 3.5 billion liters in 2024 to more than 5.1 billion liters by 2030, primarily due to the push for E20 blending and industrial use in pharmaceuticals, chemicals, and beverages.

- Grain-Based Bioethanol Leading the Way: As sugarcane supply becomes less predictable, food grains like maize and broken rice are stepping in. Grain-based bioethanol is expected to double to 4.6 billion liters by 2025–26, surpassing molasses-based bioethanol production.

- Favorable Policies & Incentives: Government support through feedstock flexibility, interest subvention, and guaranteed procurement programs reduce risk and improve investor confidence.

- Rural Development & Job Creation: Bioethanol plant development not only meets energy goals but also generates employment and improves rural income by creating a dependable market for agricultural produce.

With the right mix of policy, technology, and demand, the Indian bioethanol market presents a compelling opportunity for investors, entrepreneurs, and businesses looking to enter the green energy sector. For those ready to act, the time to invest is now.

Here’s how the government is supporting this bioethanol revolution to steer growth.

Policy Support: Enabling Grain‑Bioethanol Renaissance

India’s rapid shift toward grain-based bioethanol has been made possible by strong government policies. These steps have created a supportive environment for investors, farmers, and bioethanol plant developers.

Here’s how policy is driving the grain-bioethanol boom:

- Expanded Feedstock List: The government now allows the use of surplus rice, maize, damaged food grains, and even wheat under the Ethanol Blended Petrol (EBP) program.

- Grain Procurement for Bioethanol: The Food Corporation of India (FCI) has been actively diverting excess grain stocks for bioethanol production. In mid-2025, over 5.2 million metric tonnes of rice were allocated for this purpose.

- Minimum Support Price (MSP) for Maize: The MSP for maize was increased to ₹2,090 per quintal, encouraging more farmers to grow bioethanol-grade maize.

- Financial Incentives: The government provides interest subvention and capital support for setting up new bioethanol plants, especially grain-based ones.

- Targeted Blending Mandates: India aims for 20% bioethanol blending (E20) by 2025–26, pushing up demand and creating a secure market for producers.

These policy moves have reduced risk and improved profitability for grain-bioethanol ventures, making India one of the fastest-growing bioethanol markets globally.

Here are a few success stories that explain how the bioethanol production rate is increasing in India.

Grain‑Based Bioethanol Projects: Success Stories

Several large-scale projects across India highlight the success of grain-based bioethanol production and its growing potential:

- Gujarat Biofuel Hub: Gujarat has emerged as a leading state for grain-based bioethanol. Major players like Grainspan, Chiripal, and Amul have invested in plants with a combined capacity of over 2,800 KLPD, attracting investments worth ₹3,300 crore.

- FCI’s Grain Allocation: The Food Corporation of India diverted 5.2 million metric tonnes of surplus rice in 2025 for bioethanol production, easing storage pressure and boosting fuel supply.

- Flexible Multi-Feedstock Plants: New projects are designed to use maize, rice, or broken grains, ensuring year-round operation regardless of crop cycles.

These success stories show that India is not just scaling bioethanol production—it’s doing it smartly, using local resources and innovative technology.

For the bio ethanol from food grains plant set up and local resource allocation, you need the professional assistance of top bioethanol plant manufacturers in India. This is where MAGTECH’s expertise and experience come into play.

Technological Potential to Solve Industry Challenges: MAGTECH’s Edge

Choosing the right partner is crucial for the success of your bioethanol venture. MAGTECH stands out as a trusted and experienced solution provider for grain-based bioethanol plants. Here’s why:

- Proven Expertise: Years of experience in setting up efficient bioethanol plants across India.

- Multi-Feedstock Flexibility: Plants are designed to process maize, broken rice, and other food grains, ensuring year-round production.

- High Yield Efficiency: Advanced fermentation technology delivers higher bioethanol output per metric tonne of grain, boosting profitability.

- Modular & Scalable Design: Start with a smaller setup and scale up as your production needs grow, reducing initial investment risks.

- End-to-End Services: From design and engineering to installation, automation, and commissioning—everything is taken care of.

- Regulatory Support: MAGTECH helps you navigate government approvals, compliance, and policy incentives with ease.

- Smart Automation: Plants come equipped with modern control systems for real-time monitoring, efficiency, and safety.

We don’t just build bioethanol plants — we create a foundation for long-term success in your biofuel venture. If you’re planning a Bio ethanol from food grains plant set up, we bring the expertise and support you need to succeed. As India’s biofuel sector rapidly expands, we position ourselves as the trusted partner you can count on for every step of the process.

Power Your Green Bioethanol Future with MAGTECH’s Proven Expertise

India’s shift to grain-based bioethanol is unlocking new opportunities in green energy. With over 10 years of experience in the biofuel sector, we are the trusted partner for building efficient, future-ready bioethanol plants.

Backed by trained engineers, researchers, and experts, we deliver end-to-end solutions that work. Ready to start your bioethanol journey?

Contact MAGTECH today and take the first step toward a sustainable, profitable future.